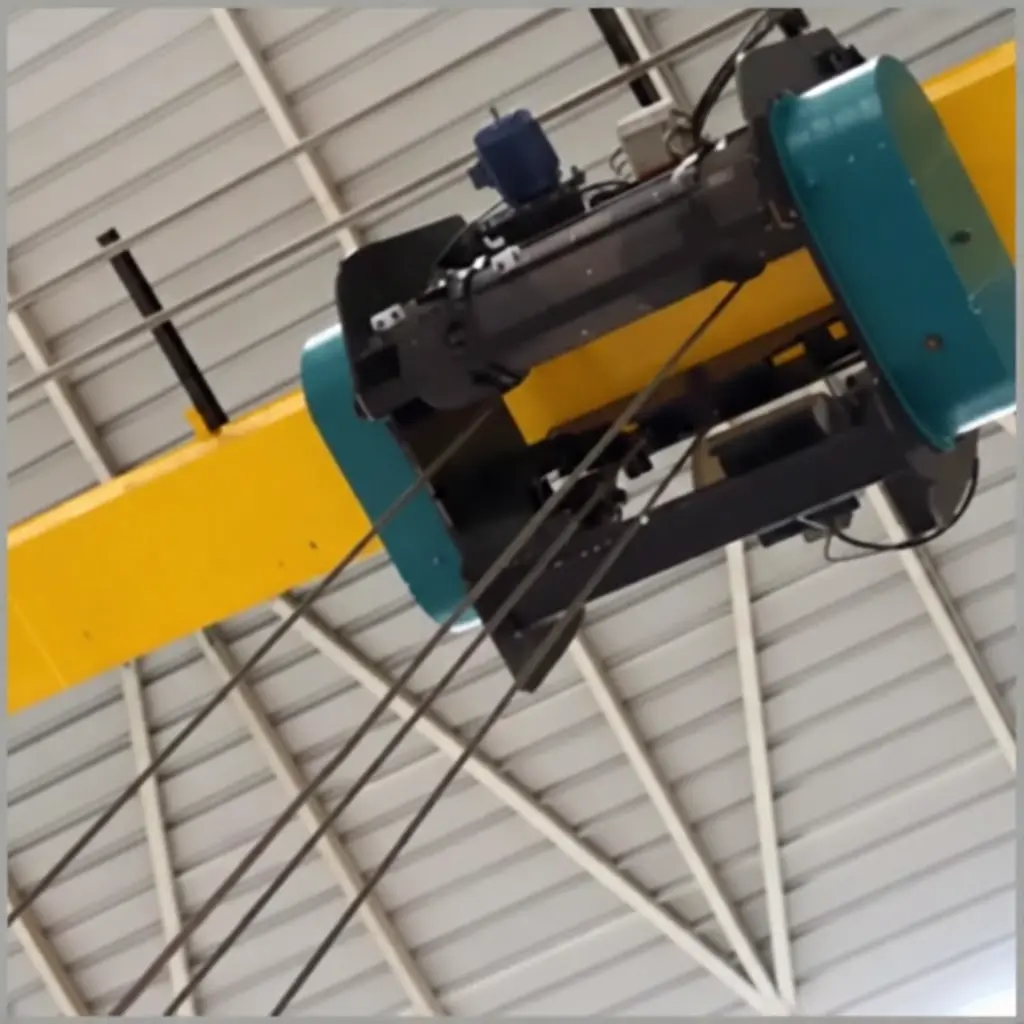

Single Overhead/Double Girder EOT and HOT Crane

We cater to the demands of our clients, and offer best quality range of overhead girder cranes with specialities of eot crane and hot crane. Modheshwari fabricates a range encompasses single girder cranes, double girder cranes, eot overhead cranes and hot overhead cranes. These overhead cranes (bridge cranes) are highly reliable as they are fabricated by a team of professionals and are tested for quality at various level of production.

Our fabricated girder overhead cranes adapt to different applications due to their various girder connection modifications. The single girder overhead crane and double girder overhead crane is a good choice for special solutions like lifting and transporting material. They are often used where high speeds and heavy service are necessary.

Our cranes are acknowledged for their salient features like high resistance to fire & corrosion, dimensional accuracy, best performance and long service life. It has enabled us to carve a niche for Modheshwari Fabricators in indian and foreign market.

Technical Specifications

| Feature | Specification |

|---|---|

| Capacity | up to 40 ton |

| Span | Up to 30 mtr |

| Long Travel Speed | Up to 15 mtr/min |

| Cross Travel Speed | Up to 15 mtr/min |

- Its simple construction reduces the moderate cost.

- Suitable for short headroom

- Small capacity types with centre span

- Easily move on antifriction ball bearing in oil bath, giving positive splash lubrication.

Design

Modheshwari E.O.T Cranes & H.O.T Cranes are designed, manufacturing, erection and testing in according with IS – 3177, for overhead traveling crane.

Safety & Duty Class Standards

Our cranes are designed in accordance with Class I & II for medium duty and Class III & IV for heavy-duty operations, ensuring maximum safety as per customer requirements.

Robust Structural Construction

All structural parts are designed as per IS-807 and manufactured using high-quality steel confirming to IS-226 for unmatched durability and reliability.

High-Performance Drive System

All drive units are engineered to deliver smooth, efficient, and long-lasting performance under rigorous industrial conditions.

Advanced Modular Hoist Design

Hoists are built according to IS-3938 in modular construction with short headroom and antifriction ball bearings in an oil bath for superior lubrication and low maintenance.

Maintenance-Friendly Engineering

Our crane design is simplified to ensure quick repairs, easy inspection, and minimal downtime during maintenance operations.

Heavy-Duty Lifting Components

Heavy-duty forged hooks (IS-3815) and special plough steel wire ropes (IS-2266) ensure maximum safety and high load-handling capacity. Twin or central LT drive arrangements are available on request.

Motors & Brakes

- The motors used are specially crane duty suitable for frequent starting, reversing and braking in accordance with IS 325.

- All trolley are drive motors have suitable AC / DC / brakes as std. equipments with smooth running properties.

Controls

- The crane is controlled from pendent push button station is suspended from one end of bridge at a suitable height from the floor level, operating at 110 V or 420 V or 240 V which ensure safety to the operator.

- Dust proof powder coated sheet – metal housing consists of contactors overload relays fuses, transformers etc.

- Emergency stop button in all cranes to shutting of the power to the main connectors.

Optional Features

Micro speed arrangement through frequency inverters / variable frequency drives..

Motors & Brakes

All structural parts of crane are applied with single coat of primer and two coats of synthetic enamel paints

Epoxy paint and P.U. paints are on request.